bursting strength unit-LabZenix

Description

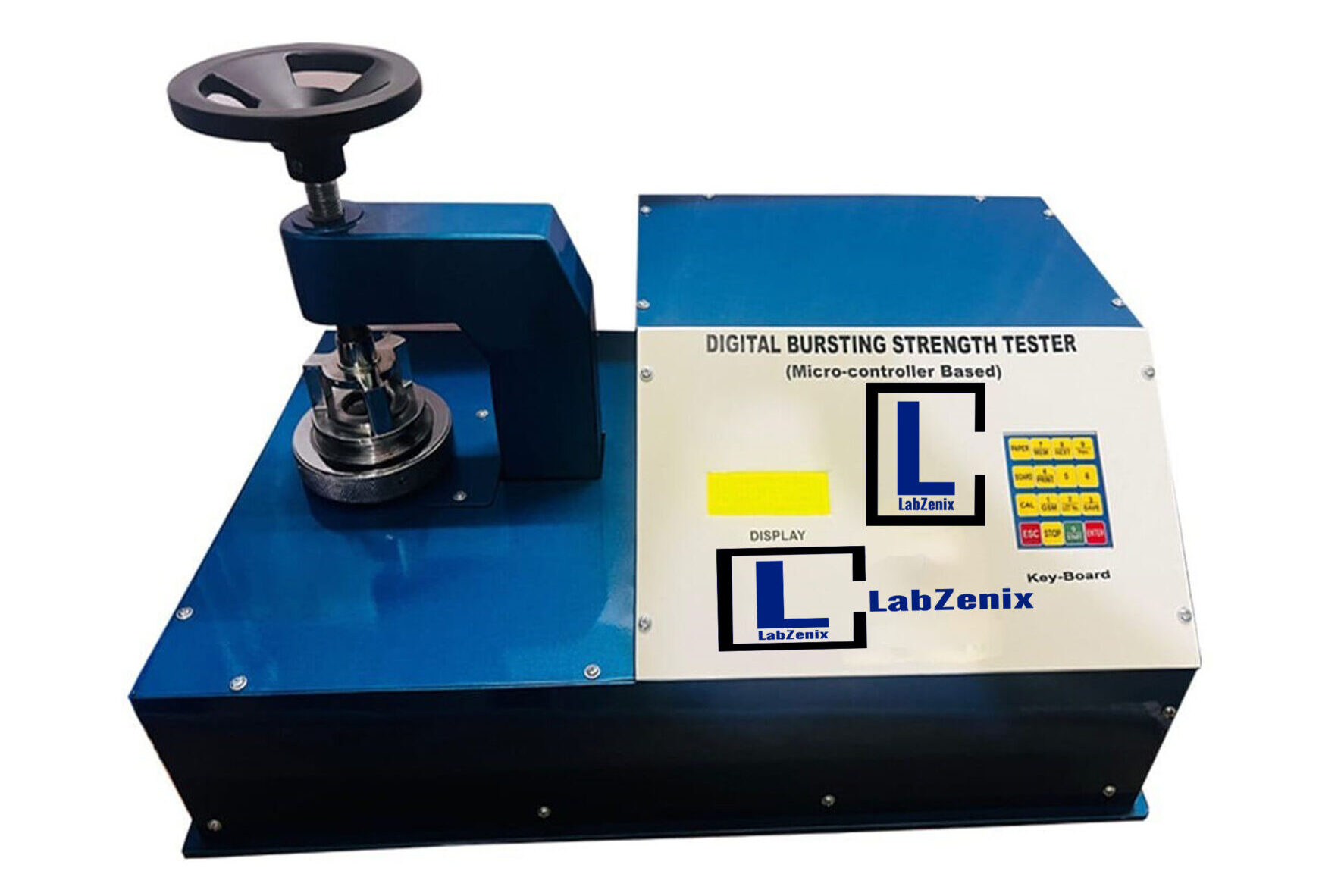

Bursting Strength Unit – LabZenix

Understanding Bursting Strength

The term “bursting strength unit” refers to a material’s ability to withstand pressure before it ruptures. It is a crucial metric for materials such as paper, cardboard, textiles, and various polymers, ensuring they can endure the stresses they encounter in their respective applications. LabZenix provides industry-leading tools to measure this critical parameter.

Importance of Bursting Strength in Quality Control

The bursting strength unit is pivotal in quality control processes. For manufacturers, understanding and measuring this strength ensures that materials can handle the demands of production, transportation, and end-use without failing. It is particularly vital in industries such as packaging, where the integrity of the material directly impacts product safety and customer satisfaction.

Paper and Packaging Industries

In the paper and packaging industries, bursting strength is a key indicator of a material’s durability. Packaging materials that lack sufficient bursting strength can easily fail during transportation, leading to damaged goods and increased costs. LabZenix’s equipment ensures accurate measurements, helping manufacturers maintain high standards.

Textile Applications

For the textile industry, bursting strength tests are equally important. Fabrics used in clothing, upholstery, and industrial applications need to meet specific strength criteria to ensure longevity and performance. LabZenix offers advanced solutions to accurately measure the bursting strength of various textiles, aiding in quality assurance and product development.

Measuring Bursting Strength

LabZenix provides sophisticated instruments designed to measure the bursting strength unit of different materials. The process typically involves clamping a sample of the material and applying an increasing amount of pressure until the material bursts. The maximum pressure applied before bursting is recorded as the bursting strength.

Factors Affecting Bursting Strength

Several factors can influence the bursting strength of a material. These include the material’s composition, thickness, and manufacturing process. Understanding these factors is essential for manufacturers to produce materials that meet the necessary standards for their specific applications.

Material Composition

The composition of a material plays a significant role in determining its bursting strength. Different fibers, additives, and treatments can either enhance or diminish a material’s ability to withstand pressure. LabZenix’s equipment is designed to accommodate various material types, ensuring accurate and reliable testing across different industries.

Thickness and Density

The thickness and density of a material are directly related to its bursting strength. Generally, thicker and denser materials exhibit higher bursting strength. However, this relationship can vary based on the type of material and its intended use. LabZenix’s instruments allow for precise control and measurement, providing valuable insights for material development and quality control.

Advantages of LabZenix Testing Instruments

LabZenix stands out in the industry for its innovative testing solutions. Their instruments are designed with precision and user-friendliness in mind, making them accessible to operators of all skill levels.

Precision and Reliability

LabZenix’s testing instruments are renowned for their precision and reliability. They provide consistent and accurate measurements, which are crucial for maintaining quality standards. The advanced technology used in these instruments ensures that every test is reliable, giving manufacturers confidence in their products.

Ease of Use

Ease of use is a significant advantage of LabZenix instruments. The intuitive interfaces and straightforward controls make the testing process simple and efficient. This user-friendly design reduces the learning curve for operators, minimizing errors and increasing productivity.

Comprehensive Support

LabZenix is committed to supporting its customers with comprehensive training, technical assistance, and maintenance services. This dedication ensures that users get the most out of their testing instruments, maintaining optimal performance throughout the equipment’s lifespan.

Applications of Bursting Strength Testing

The applications of bursting strength testing are vast and varied, encompassing multiple industries that rely on strong, durable materials.

Packaging and Shipping

In the packaging and shipping sectors, ensuring that packaging materials can withstand the rigors of transport is critical. Bursting strength tests help manufacturers produce robust packaging solutions that protect their contents effectively.

Textile Manufacturing

For textile manufacturers, bursting strength testing ensures that fabrics can endure daily wear and tear. This testing is crucial for products like upholstery, which must withstand significant stress over their lifetime.

Future Trends in Bursting Strength Testing

As industries continue to innovate, the need for precise and reliable material testing will only grow. LabZenix remains at the forefront of this field, continuously developing new technologies and methods to meet evolving industry standards.

Technological Advancements

Future advancements in bursting strength testing will likely involve more sophisticated sensors and automated testing processes. These improvements will enhance accuracy and efficiency, making it easier for manufacturers to maintain high-quality standards.

Sustainability and Testing

As sustainability becomes a key focus across industries, the role of material testing in developing eco-friendly products will be crucial. LabZenix’s commitment to precision and innovation ensures that their testing instruments will continue to support sustainable practices.

The bursting strength unit is a critical metric for assessing the durability of various materials. LabZenix offers state-of-the-art testing instruments that provide accurate, reliable, and consistent measurements. By understanding and utilizing these tools, manufacturers can ensure their products meet the highest quality standards, ultimately benefiting their businesses and customers alike.

LabZenix continues to lead the way in material testing, providing the tools and support necessary to navigate the challenges of modern manufacturing. With their advanced solutions, you can confidently ensure the integrity and reliability of your materials, securing a competitive edge in your industry.

Bursting Strength Unit – LabZenix: Specifications and Features

Introduction to LabZenix Bursting Strength Unit

The LabZenix Bursting Strength Unit is a precision instrument designed to measure the bursting strength of materials such as paper, cardboard, textiles, and polymers. This guide details the specifications and features that make the LabZenix unit a leading choice for industries requiring accurate and reliable bursting strength measurements.

Technical Specifications

Measurement Range

Pressure Range: The LabZenix Bursting Strength Unit can measure pressures from 0 to 2000 kPa, accommodating a wide variety of materials and testing needs.

Accuracy: With an accuracy of ±0.5% of full scale, the unit ensures precise measurements every time.

Resolution: The unit features a high resolution of 0.1 kPa, providing detailed insights into material strength.

Construction and Design

Materials: The unit is constructed from high-grade stainless steel and durable polymers, ensuring long-term durability and resistance to wear and tear.

Dimensions: The compact design measures 400 mm x 500 mm x 600 mm, making it suitable for laboratories with limited space.

Weight: Weighing in at 30 kg, the unit is portable yet stable, allowing for easy repositioning without compromising accuracy.

Display and Interface

Digital Display: The LabZenix unit features a clear, backlit digital display that shows real-time pressure readings and test results.

Touchscreen Interface: The user-friendly touchscreen interface allows for easy navigation, setting adjustments, and data entry.

Multilingual Support: The interface supports multiple languages, making it accessible to users around the world.

Key Features of LabZenix Bursting Strength Unit

Advanced Sensor Technology

The LabZenix Bursting Strength Unit is equipped with state-of-the-art sensors that provide accurate and consistent measurements. These sensors are designed to detect even the slightest changes in pressure, ensuring the highest level of precision.

Automatic Calibration

Self-Calibrating: The unit features an automatic calibration system that adjusts the sensors regularly to maintain accuracy.

Calibration Alerts: Users are notified when calibration is due, preventing errors and ensuring consistent performance.

User-Friendly Operation

Intuitive Controls: The touchscreen interface and simple control layout make the unit easy to operate, even for users with minimal training.

Pre-Set Programs: The unit comes with pre-set testing programs for different materials, simplifying the setup process.

Customizable Settings: Users can create and save custom test settings, allowing for tailored testing procedures.

Safety Features

Overpressure Protection: The unit is equipped with an overpressure protection system that automatically shuts down the test if pressure exceeds safe limits.

Emergency Stop: An emergency stop button allows users to halt the test immediately if needed.

Data Management and Connectivity

Data Storage: The unit can store up to 1,000 test results internally, ensuring that important data is never lost.

USB and Ethernet Ports: These ports allow for easy data transfer to external devices for analysis and record-keeping.

Software Integration: The unit is compatible with LabZenix’s proprietary software, which offers advanced data analysis and reporting features.

Robust Construction

Heavy-Duty Build: The use of high-quality materials ensures that the unit can withstand the demands of frequent testing.

Corrosion-Resistant: All components are designed to resist corrosion, extending the life of the unit in various environments.

Stable Base: The unit’s stable base minimizes vibrations and movement during tests, ensuring accurate readings.

Maintenance and Durability

Easy Maintenance: The unit is designed for easy maintenance, with accessible components and clear maintenance instructions.

Long Lifespan: The durable construction and high-quality materials ensure a long operational lifespan, providing excellent return on investment.

Applications of LabZenix Bursting Strength Unit

Paper and Packaging Industries

Corrugated Boxes: Ensuring that boxes can withstand stacking and handling.

Paperboard: Verifying the strength of paperboard used in packaging.

Textile Industry

Fabrics: Testing the durability of fabrics used in clothing and upholstery.

Industrial Textiles: Ensuring that textiles used in industrial applications meet strength requirements.

Polymers and Plastics

Film Testing: Measuring the strength of plastic films used in packaging.

Composite Materials: Testing the strength of polymer-based composite materials.

Conclusion

The LabZenix Bursting Strength Unit is a versatile and reliable instrument designed to meet the demanding needs of various industries. Its advanced sensor technology, user-friendly operation, robust construction, and comprehensive data management capabilities make it an indispensable tool for quality control and research and development. By investing in the LabZenix unit, companies can ensure accurate and consistent bursting strength measurements, ultimately enhancing product quality and reliability.

This detailed understanding of the specifications and features of the LabZenix Bursting Strength Unit highlights its suitability for any laboratory aiming to maintain high standards in material testing.