Bottle Burst Strength Tester – Ensuring Packaging Durability

Bottle Burst Strength Tester – Ensuring Packaging Durability- LabZenix

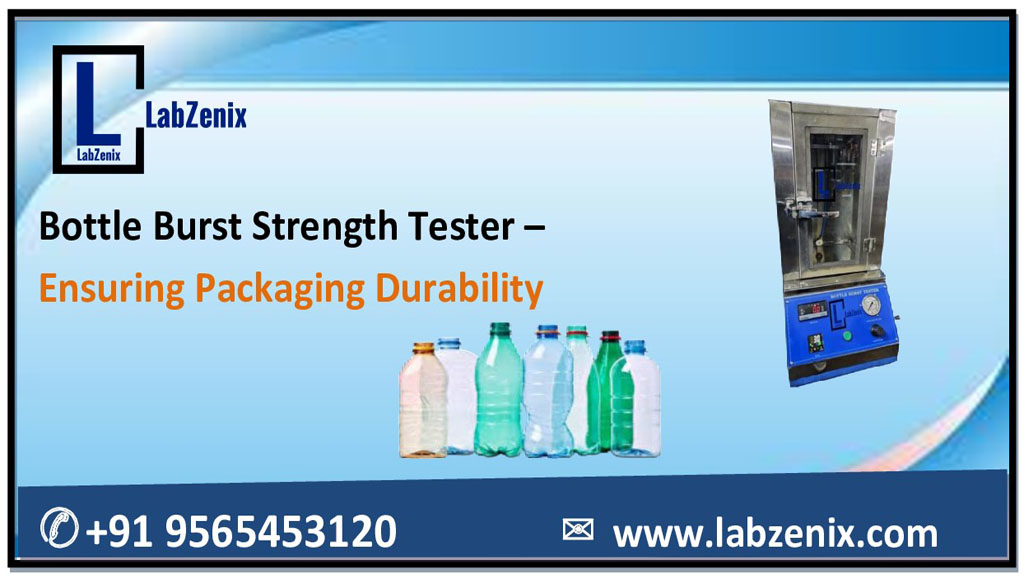

The packaging industry needs to guarantee the bottles are durable and strong enough to avoid leakage or breakage or damage during transport and storage. An important laboratory device for measuring the pressure resisting ability of bottles according to the industry standards is the Bottle Burst Strength Tester.

Description

Bottle Burst Strength Tester – Ensuring Packaging Durability and Safety

The packaging industry needs to guarantee the bottles are durable and strong enough to avoid leakage or breakage or damage during transport and storage. An important laboratory device for measuring the pressure resisting ability of bottles according to the industry standards is the Bottle Burst Strength Tester. This article gives insight into the importance, working principle, applications, and advantages of using the Bottle Burst Strength Tester, along with some frequently asked questions.

What is a Bottle Burst Strength Tester?

This machine is used by bottle manufacturers for maximum rupture pressure testing. This test helps evaluate the structural integrity of bottles made from materials such as plastic, glass, or PET. The instrument simulates real field conditions so the bottles are expected to survive physical handling, stacking, transportation, etc.

Why is Bottle Burst Testing Important?

Quality Assurance – Ensures bottles meet industry standards and can withstand pressure variations.

Prevents Product Loss – Identifies weak bottles that may burst during filling, capping, or shipping.

Enhances Safety – Reduces the risk of injuries caused by exploding bottles.

Regulatory Compliance – Helps manufacturers comply with international packaging standards like ASTM, ISO, and ISTA.

Cost-Effective Production – Detects defects early, reducing waste and improving production efficiency.

How Does a Bottle Burst Strength Tester Work?

The Bottle Burst Strength Tester operates by applying increasing pressure to a sealed bottle until it bursts. Here’s a step-by-step breakdown of the testing process:

Sample Preparation – The bottle is filled with water or air and securely sealed.

Placement in Testing Chamber – The bottle is placed inside the tester’s pressure chamber.

Pressure Application – Hydraulic or pneumatic pressure is gradually increased.

Burst Detection – The instrument records the exact pressure at which the bottle fails.

Data Analysis – The results are displayed and stored for quality control reports.

Key Features of a High-Quality Bottle Burst Strength Tester

Digital Pressure Display – Provides accurate and real-time pressure readings.

Adjustable Pressure Settings – Allows customization based on bottle material and size.

Safety Mechanisms – Includes overload protection and emergency stop functions.

Data Logging – Stores test results for future reference and compliance reports.

User-Friendly Interface – Easy-to-operate controls for efficient testing.

Applications of Bottle Burst Strength Tester

The Bottle Burst Strength Tester is widely used in industries such as:

Beverage Industry – Ensures soda, juice, and water bottles can withstand carbonation pressure.

Pharmaceuticals – Tests medicine bottles for leak-proof packaging.

Cosmetics & Personal Care – Verifies the durability of shampoo, lotion, and perfume bottles.

Food Packaging – Checks the strength of oil, sauce, and condiment bottles.

Chemical Industry – Ensures chemical containers are safe for hazardous liquids.

Advantages of Using a Bottle Burst Strength Tester

Accurate Results – Provides precise measurements for quality control.

Durability Testing – Simulates real-world conditions to assess bottle performance.

Prevents Financial Losses – Reduces recalls and product damage by identifying weak packaging.

Enhances Brand Reputation – Ensures customers receive intact and safe products.

Improves Manufacturing Processes – Helps optimize bottle design and material selection.

FAQs About Bottle Burst Strength Tester

1. What is the purpose of a Bottle Burst Strength Tester?

The Bottle Burst Strength Tester evaluates the maximum pressure a bottle can withstand before bursting, ensuring it meets safety and quality standards.

2. Which industries use this tester?

Beverage, pharmaceutical, cosmetic, food packaging, and chemical industries rely on this tester for quality assurance.

3. Can the tester be used for different bottle materials?

Yes, the Bottle Burst Strength Tester works with plastic, PET, glass, and other bottle materials.

4. How is burst strength measured?

The tester applies increasing pressure until the bottle ruptures, recording the exact pressure at failure.

5. Are there safety features in the tester?

Yes, modern testers include overload protection, emergency stops, and secure testing chambers for operator safety.

6. What standards does the tester comply with?

It adheres to ASTM D3078, ISO 7458, and other international packaging standards.

7. How often should burst testing be performed?

Manufacturers should test samples from each production batch to ensure consistent quality.

8. Can the tester store test data?

Yes, advanced models include data logging for compliance documentation and analysis.

9. What is the difference between burst strength and leak testing?

Burst strength measures pressure resistance, while leak testing checks for seal integrity under low pressure.

10. How does burst testing improve product safety?

By identifying weak bottles, manufacturers can prevent explosions and ensure consumer safety.

Final Thoughts

The Bottle Burst Strength Tester is a necessary instrument for the maintenance of packaging integrity in various sectors. Through efficient testing and accurate measurement of pressure resistance of bottles, manufacturers improve safekeeping of products, reduce waste and comply with global standards. Therefore, high investment in quality Bottle Burst Strength Tester will provide a long-term reliability that satisfies customers.

For more details on selecting the right Bottle Burst Strength Tester, contact LabZenix today!

Contact – LabZenix

Pingback: High-precision bottle burst tester for laboratories » LABZENIX TESTING INSTRUMENTS